You’re specifying an acoustic enclosure for a corporate project. The standard catalogue options look reasonable. Dimensions are close enough. Finishes are acceptable. You could make it work. But “close enough” and “acceptable” aren’t words that belong in professional architecture.

The difference between standard and custom acoustic enclosures isn’t just about getting exactly what you want. It’s about whether your acoustic enclosure manufacturer has the design capabilities to solve your actual problem rather than offering you their standard solution and hoping it fits.

Acoustic enclosures – from single-person phone booths to multi-person meeting pods – are only as good as the manufacturer’s ability to customise them for your specific needs. Whether you’re specifying a Unipod-style acoustic booth or a larger collaboration space, design capabilities determine success.

The Standard Solution Trap

Standard acoustic enclosures exist because they solve common problems reasonably well. A single-person phone booth for an open office. A four-person meeting pod with basic configurations. These products serve a purpose, and for straightforward applications, they work adequately.

The problem emerges when your project isn’t straightforward. And most projects aren’t.

Your ceiling height is lower than the standard pod requires. Your floor loading has restrictions. Your brand colours don’t match the three standard options. Your space layout needs a phone booth with one glass wall instead of two. Your acoustic requirements are more demanding than the standard specification delivers.

This is where manufacturer design capabilities become critical. An acoustic enclosure manufacturer with only standard products will tell you what compromises you need to make. A manufacturer with genuine design capabilities will tell you how to avoid those compromises.

What Design Capabilities Actually Mean

When evaluating an acoustic enclosure manufacturer, “design capabilities” sounds vague. In practice, it means specific technical and manufacturing competencies that separate capable manufacturers from product distributors.

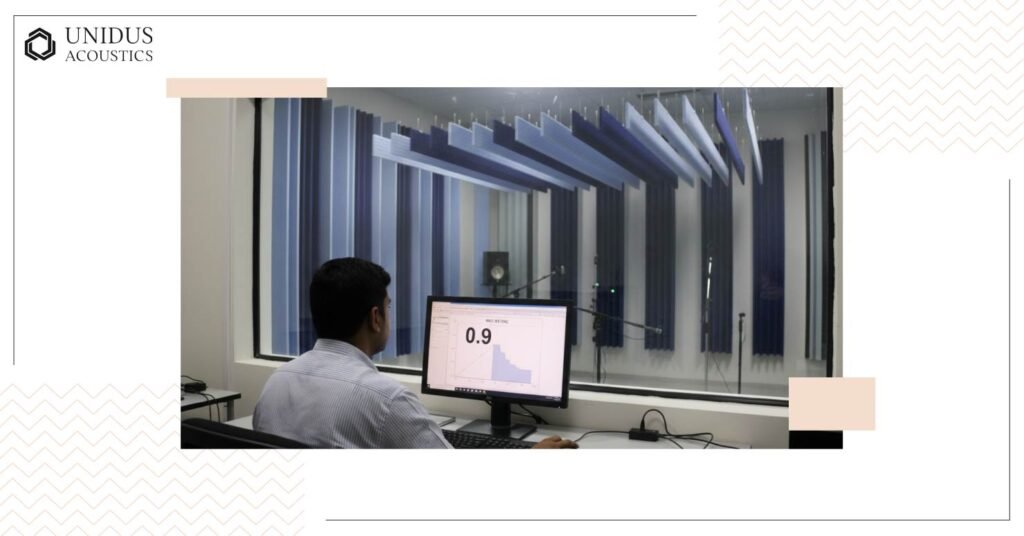

Computational Design

Advanced manufacturers use computational modelling to design acoustic enclosures that meet specific performance requirements. This isn’t just adjusting dimensions. It’s modelling how sound will behave inside the enclosure, how different materials affect acoustic performance, and how structural elements impact both acoustics and aesthetics.

Material Flexibility

Design capability means working with multiple materials and understanding their acoustic properties. Wood, metal, fabric-wrapped panels, glass specifications, each material affects sound absorption, sound isolation, and visual integration differently. Manufacturers with design capabilities can specify the right materials for your requirements rather than being limited to whatever their standard product uses.

Engineering Integration

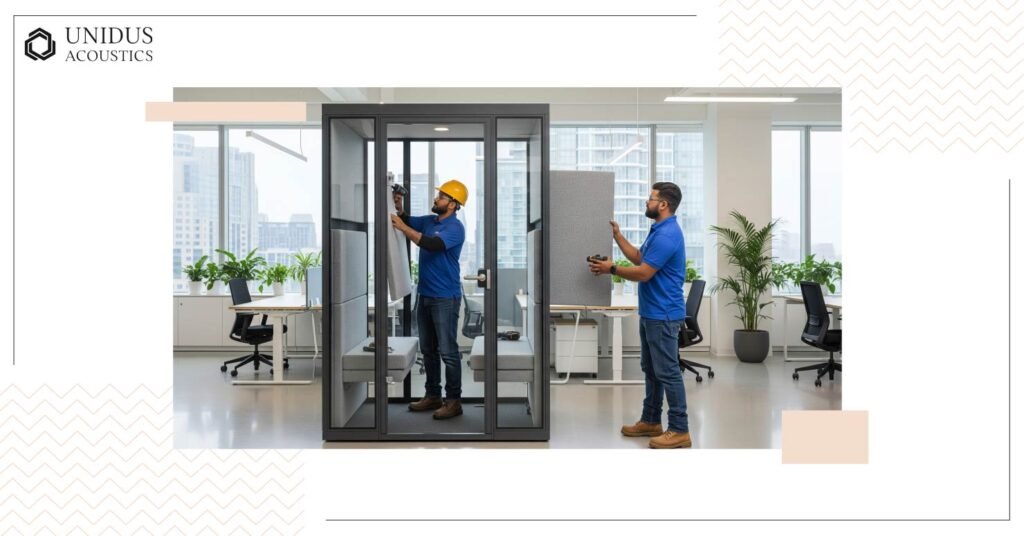

Custom acoustic pods and phone booths need proper engineering. Structural integrity, ventilation systems, electrical integration, and lighting design, these elements must work together. Manufacturers with design capabilities have engineering resources to ensure the enclosure functions as a complete system.

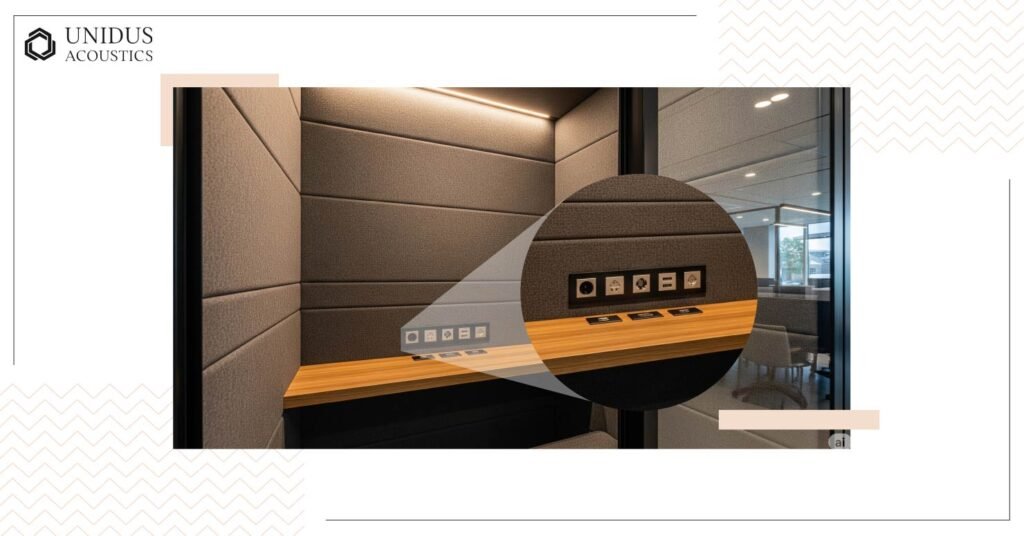

For example, our Unipod AS1 Quick Call Booth demonstrates this integration: double-glazed glass for sound isolation, sensor-based LED lighting, multi-way ventilation systems, and universal sockets with USB charging – all engineered to work together seamlessly.

Prototyping and Testing

Real design capability includes the ability to prototype, test, and refine. This matters particularly when you’re pushing boundaries on size, configuration, or performance requirements.

Where Custom Design Delivers Value

The value of custom design capabilities becomes obvious in specific scenarios that happen more often than you might expect.

Non-Standard Dimensions

Building constraints often dictate enclosure size. Ceiling heights vary. Floor space is limited. Circulation paths restrict placement. An acoustic enclosure manufacturer with design capabilities can engineer phone booths and meeting pods that fit your space rather than forcing you to adapt your space to their product’s dimensions.

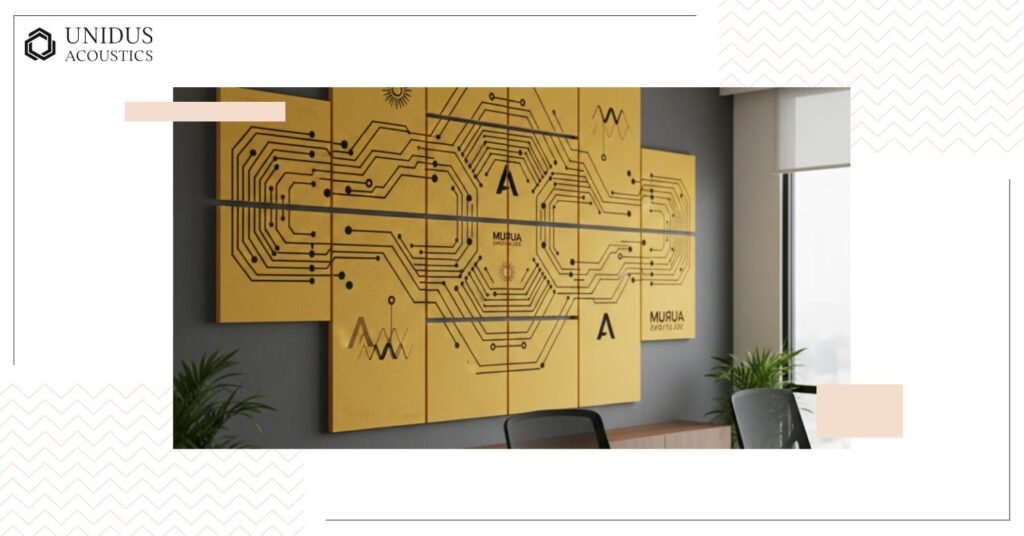

Aesthetic Integration

Corporate spaces have brand guidelines. Hospitality venues have design themes. Institutional projects have architectural languages. Custom design capabilities allow the acoustic enclosure to match your aesthetic vision completely. Not three standard colours, but your exact colour specification. Not generic finishes, but materials that complement the surrounding space.

Acoustic Performance Requirements

Different spaces need different acoustic performance. A confidential discussion room needs higher sound isolation than a focus booth. A creative collaboration pod (like our Unipod AL1 for 4-6 people) might need different internal acoustics than an individual phone booth (like our Unipod AS1). Manufacturers with design capabilities can engineer acoustic solutions to meet specific acoustic targets rather than offering generic performance specs.

Technical Integration

Modern workspaces demand technical integration. Custom power configurations. Integrated AV systems. Specific ventilation requirements. Climate control integration. Manufacturers with design capabilities can incorporate these elements into the pod or booth design rather than forcing awkward add-ons.

Accessibility Requirements

Universal design isn’t optional. Acoustic pods and phone booths must accommodate all users. Custom design capabilities allow manufacturers to meet accessibility standards while maintaining acoustic performance and aesthetic quality.

The Cost Question

Here’s what most people assume: custom design capabilities mean custom pricing, and custom pricing means expensive. This assumption misses the actual economics.

Standard products are priced for volume production and broad market appeal. They include features some customers need and others don’t. You pay for engineering that happened once and is now amortised across thousands of units.

At Unidus Acoustics, our custom Unipod designs balance bespoke capabilities with efficient manufacturing, giving you tailored acoustic solutions without unnecessary cost inflation. Yes, custom design involves engineering time, but it eliminates waste, reduces the need for workarounds, and prevents the cost of discovering after installation that the standard product doesn’t quite work.

More importantly, custom design capabilities from an experienced acoustic enclosure manufacturer often cost less than you expect because the manufacturer understands how to achieve your requirements efficiently. They know which customisations affect cost significantly and which don’t. They can guide you toward solutions that deliver what you need without unnecessary expense.

Value for money comes from getting what your project actually requires, not from accepting what happens to be in stock.

Red Flags When Evaluating Manufacturers

Some warning signs indicate a manufacturer lacks genuine design capabilities, even if they claim to offer custom solutions.

Limited Material Options: If everything they show uses the same materials and construction methods, they’re not designing custom solutions. They’re modifying a standard product.

At Unidus Acoustics, we work with multiple materials – wood, metal, fabric-wrapped panels, various glass specifications – to match your project’s needs.

Slow or Vague Responses to Custom Requests: Manufacturers with real design capabilities can quickly assess whether your requirements are feasible. Vague answers or long delays suggest they’re trying to figure out if they can do it rather than how to do it best.

No Engineering Documentation: Custom acoustic enclosures need proper engineering documentation. Structural calculations. Acoustic performance data. Ventilation specifications. If the manufacturer can’t provide this, they don’t have design capabilities.

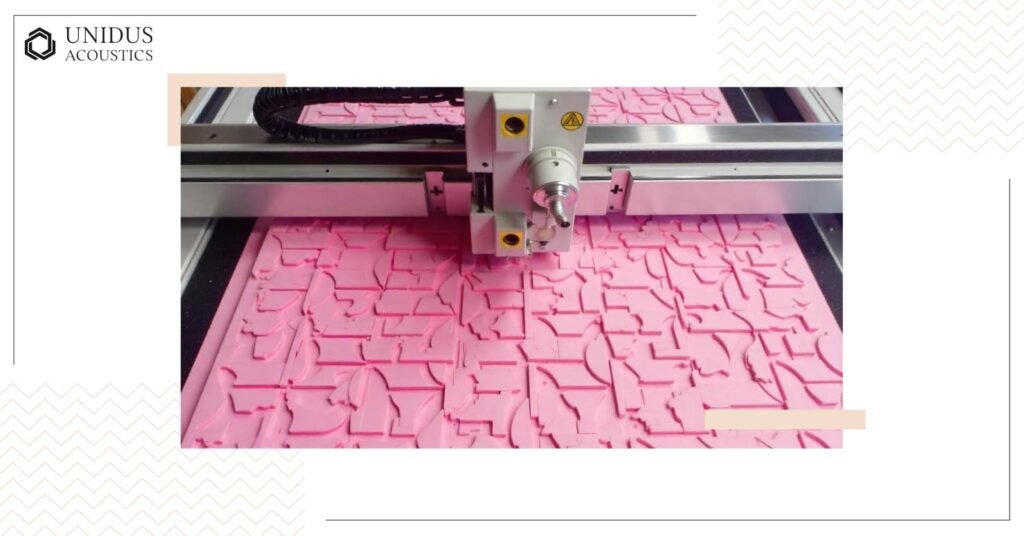

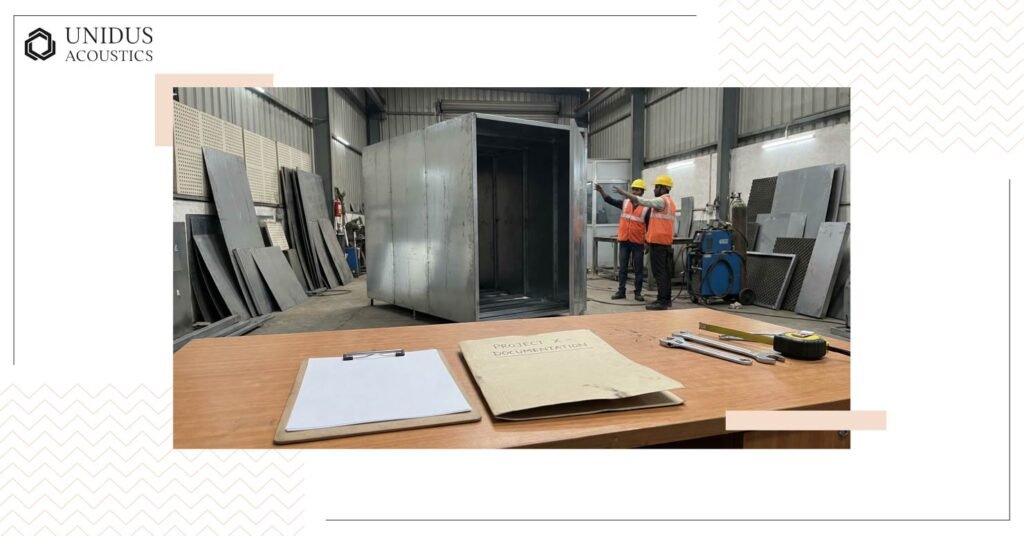

Reluctance to Discuss Manufacturing Process: Manufacturers with design capabilities are transparent about how they manufacture custom solutions. They have the facilities, equipment, and expertise to deliver what they promise.

What to Look for Instead

When your project needs custom acoustic enclosures, evaluate potential manufacturers based on actual capabilities rather than marketing claims.

Look for computational design capabilities that allow the manufacturer to model acoustic performance before building. Ask about their prototyping process and how they verify performance. Review their material options and understand why they recommend specific materials for your application.

Examine previous custom projects. Not just photos, but the technical requirements those projects addressed. How did the manufacturer solve unusual constraints? What acoustic performance did they achieve? How did they handle integration challenges?

Ask about manufacturing capabilities. Do they control the manufacturing process or outsource it? What quality control systems ensure consistent performance? How do they handle on-time delivery for custom products?

At Unidus Acoustics, our 40 years of expertise includes comprehensive design and manufacturing capabilities. Our computational design approach allows us to create acoustic enclosures that meet your exact requirements while maintaining on-time delivery. We don’t just modify standard products. We design solutions that balance acoustic performance, aesthetic integration, and value for money.

Making the Right Choice

The choice between standard and custom acoustic enclosures isn’t really about budget. It’s about whether standard solutions actually solve your problem or whether they force compromises that affect the project’s success.

An acoustic enclosure manufacturer with genuine design capabilities gives you options. You can choose standard solutions when they work or custom solutions when they’re needed. Manufacturers without design capabilities give you standard products and expect you to make them work regardless of your requirements.

Your role as an architect or designer is to specify solutions that serve the project, not to adapt projects to available products. Choose an acoustic enclosure manufacturer whose design capabilities support that goal.

Need acoustic enclosures – phone booths, meeting pods, or custom acoustic solutions – that match your exact requirements?

Get in Touch

With our team to discuss custom design solutions that deliver the acoustic performance, aesthetic integration, and value your project demands.