Six months ago, an architect called about a problem that’s becoming all too common. Beautiful new office space in Cyber City with soaring ceilings, exposed concrete, and industrial lighting – the works. But employees couldn’t work there. Every conversation echoed. Phone calls were impossible. The space looked incredible, but sounded terrible.

The facilities manager had already tried the obvious solution: acoustic panels on walls. Lots of them. The panels helped a bit, but the fundamental problem remained. Sound was bouncing around horizontally before it ever hit those wall-mounted panels.

That’s precisely the problem ceiling baffles solve. They intercept sound travelling horizontally through a space – the kind of noise that wall panels miss entirely. Within two months of installing a well-designed baffle system, that office went from an acoustic nightmare to a productivity haven.

This guide covers everything you need to know about ceiling baffles: when they work, how to choose the right system, what to specify, and how to avoid the common mistakes that compromise both performance and aesthetics.

Understanding Ceiling Baffles: Why They Work Where Panels Don’t

Ceiling baffles are suspended acoustic elements that hang from the ceiling to control echo and reduce overall noise levels. But they work differently from the acoustic panels most people are familiar with.

Standard acoustic panels mount flush against walls or ceilings. They only absorb sound that hits them directly. In most commercial spaces, that’s actually a small percentage of the total sound energy. Most noise – conversations, phone calls, equipment – travels horizontally before bouncing off surfaces.

Baffles create vertical absorptive surfaces that catch the horizontal sound travel. Think of them as acoustic nets suspended in the path of travelling sound waves. They’re particularly effective in spaces with high ceilings where traditional acoustic treatment becomes impractical.

When Baffles Make Sense

Open offices with ceiling heights above 3 metres benefit enormously from baffle systems. The higher the ceiling, the more effective baffles become compared to wall-mounted alternatives. Spaces with glass partitions or minimal wall area particularly need overhead acoustic treatment.

Retail environments use baffles to control noise without blocking sight lines. Restaurants employ them to manage conversation noise while maintaining the open atmosphere that makes dining enjoyable. Warehouses and manufacturing facilities rely on baffles because wall treatment simply isn’t practical in spaces that large.

Educational facilities find baffles essential for controlling noise in cafeterias, gymnasiums, and large multipurpose spaces. The key advantage: acoustic control without permanent room division.

Performance Expectations

Well-designed baffle systems typically reduce overall noise levels by 6-12 decibels and cut reverberation time significantly. In practical terms, this means conversations become clearer, phone calls stop being frustrating, and general background noise drops to comfortable levels.

The effectiveness depends heavily on coverage. Most commercial applications need 15-25% of the ceiling area covered with baffles for noticeable improvement. More coverage provides better results, but there are diminishing returns beyond 40% coverage in most spaces.

Material quality matters enormously. Budget-grade baffles may provide minimal improvement, while quality systems deliver dramatic acoustic transformation. The difference lies in the acoustic core materials and how they’re manufactured.

Types of Ceiling Baffles: Choosing the Right System

Here are the key types of ceiling baffles you can explore:

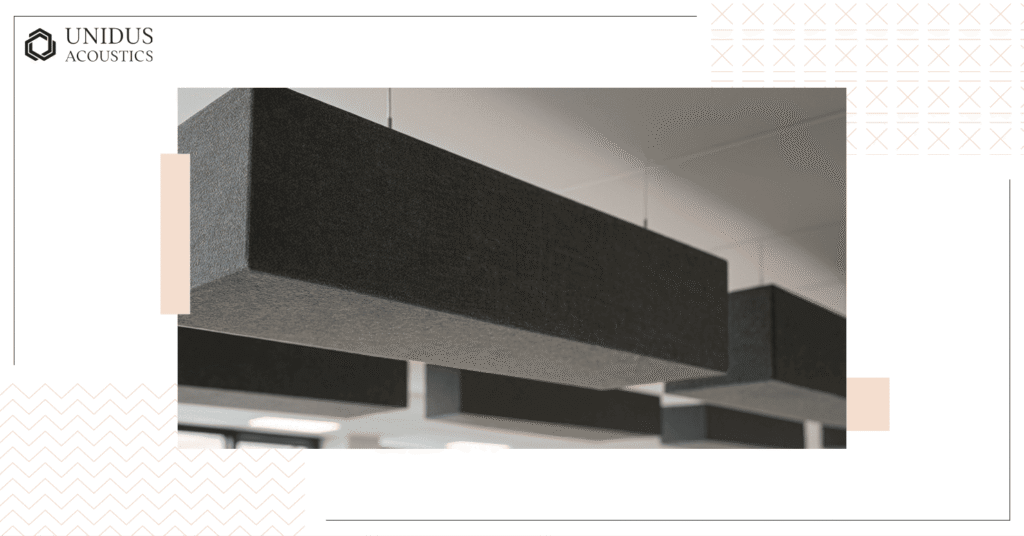

Fabric-Wrapped Baffles: Maximum Performance

Fabric-wrapped systems offer the best acoustic performance of any baffle type. Dense fibreglass or mineral wool cores provide excellent sound absorption across all frequency ranges. Fabric covering enables unlimited design options while maintaining acoustic effectiveness.

These systems excel where acoustic performance is the primary concern. Corporate offices, healthcare facilities, and educational buildings benefit from the superior noise reduction that the fabric baffles provide. The acoustic improvement often justifies the higher cost in environments where productivity or comfort is critical.

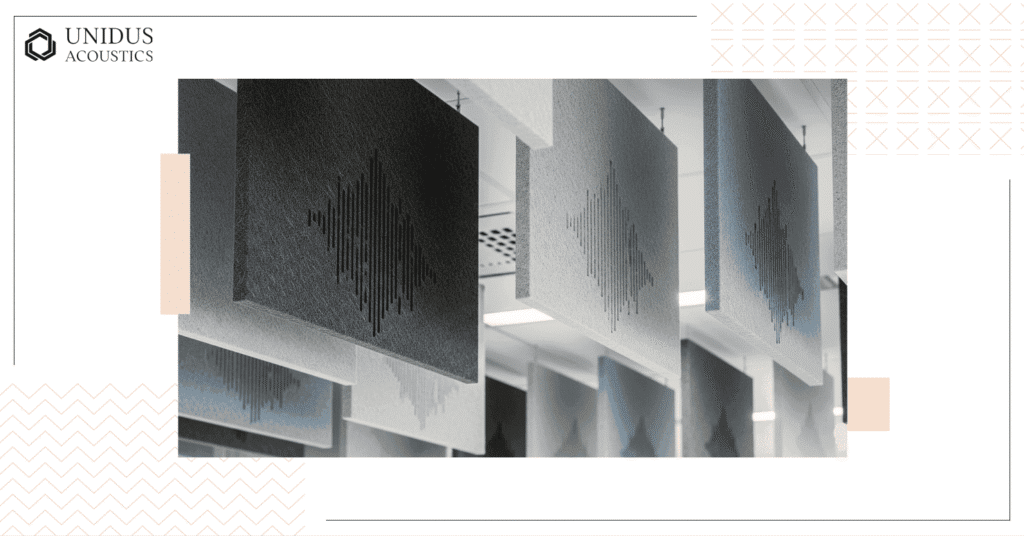

Design flexibility is a major advantage. Fabric comes in hundreds of colours and patterns. Custom printing enables corporate graphics, artistic designs, or wayfinding elements. Some installations become artwork that happens to control acoustics.

Maintenance involves eventual fabric replacement – typically after 10-15 years, depending on environment and usage. Professional cleaning can extend fabric life, but eventual replacement is part of the lifecycle cost consideration.

Wood Baffles: Aesthetic Integration

Wood baffles bring natural warmth to commercial environments dominated by hard surfaces. Perforated timber with acoustic backing provides good sound absorption while complementing architectural finishes.

Corporate headquarters, law firms, and hospitality venues appreciate wood’s professional appearance. The natural material supports biophilic design trends while delivering solid acoustic performance. Wood baffles often become architectural features that enhance rather than detract from overall design.

Customisation options include wood species, stain colours, and perforation patterns. Standard perforations provide reliable performance, while custom patterns enable unique aesthetic effects. Integrated lighting grooves transform baffles into illuminated architectural elements.

Cost considerations include premium pricing for materials and potential maintenance requirements. Quality wood baffles typically cost 40-80% more than fabric systems but offer superior durability and timeless aesthetic appeal.

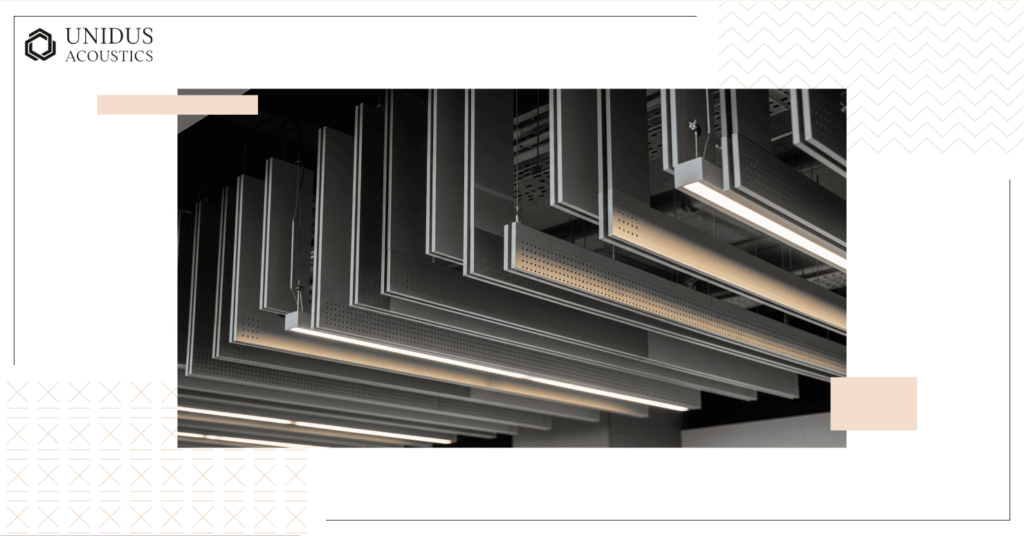

Metal Baffles: Industrial Durability

Perforated metal systems provide clean, contemporary aesthetics with reliable acoustic performance. Aluminium offers lightweight installation and corrosion resistance. Steel provides a more substantial appearance but requires protective finishes in humid environments.

Manufacturing facilities, transportation hubs, and contemporary office environments suit the metal baffles’ industrial aesthetic. The non-combustible materials meet strict fire codes often required in institutional applications.

Colour options through powder coating enable design coordination with existing architectural elements. Standard colours provide cost-effective solutions, while custom colour matching ensures perfect integration with specific design requirements.

Durability is exceptional – quality metal baffles can perform effectively for decades with minimal maintenance. This longevity often offsets higher initial costs through reduced lifecycle expenses.

Composite Systems: Sustainable Solutions

Recycled materials offer environmental benefits with performance comparable to traditional options. PET panels made from recycled plastic bottles provide excellent acoustic absorption with sustainable credentials.

These systems appeal to environmentally conscious clients pursuing LEED certification or corporate sustainability goals. The acoustic performance often exceeds traditional materials while supporting green building objectives.

Manufacturing flexibility enables complex shapes and custom designs that are impossible with traditional materials. Thermoforming capabilities create three-dimensional installations that serve as acoustic sculptures.

Cost competitiveness makes sustainable options attractive for budget-conscious projects. The environmental benefits provide additional value that supports premium positioning and corporate responsibility messaging.

Design Applications: Where Ceiling Baffles Excel

Here are some top areas where ceiling baffles can be used:

Open Office Environments

Modern office design creates beautiful spaces that often sound terrible. Open layouts, glass partitions, and hard surfaces combine to create acoustic chaos that destroys productivity. Ceiling baffles provide acoustic separation without visual barriers.

Strategic placement defines work zones within larger open areas. Baffles over collaborative spaces contain conversation noise. Different suspension heights create a subtle spatial hierarchy that guides behaviour without physical boundaries.

Integration with lighting and HVAC systems requires coordination but delivers powerful results. Baffles with integrated lighting provide task illumination while controlling acoustics. Some systems incorporate air diffusers that maintain HVAC efficiency while managing sound.

Technology companies particularly value systems that accommodate frequent space reconfiguration. Modular installations adapt to changing team sizes and work patterns without major reconstruction.

Retail and Hospitality Spaces

Retail environments need acoustic control that doesn’t interfere with sight lines or customer flow. Baffles provide overhead treatment that manages noise without blocking product displays or creating visual barriers.

Restaurant applications require a particular balance. Dining rooms need enough ambient sound for energy and atmosphere, but not so much that conversation becomes difficult. Baffles create acoustic zones that support different dining experiences within a single space.

Brand expression opportunities make baffles valuable marketing tools. Custom colours, patterns, and graphics transform acoustic treatment into brand reinforcement. Some installations feature changeable elements for seasonal promotions.

Hospitality venues use baffles to create intimate spaces within large volumes. Hotel lobbies employ suspended installations to define seating areas while maintaining visual openness. Conference centres use baffles to control echo without permanent room divisions.

Educational and Institutional Facilities

Schools face acoustic challenges that directly impact learning outcomes. Poor acoustics reduce speech clarity and student comprehension. Cafeterias and gymnasiums need acoustic control to prevent noise from disrupting adjacent learning spaces.

Durability requirements in educational environments drive material selection. Baffles must withstand impacts from sports equipment and accommodate institutional maintenance schedules. Easy cleaning and damage resistance become primary considerations.

Safety regulations affect installation methods and material choices. Non-combustible materials may be required near cooking facilities. Installation cannot interfere with sprinkler coverage or emergency lighting systems.

Large institutional spaces benefit enormously from baffle treatment because wall-mounted alternatives prove ineffective in spaces with such volumes and distances.

Industrial and Warehouse Applications

High-ceiling industrial spaces present unique challenges. Sound travels long distances in these environments, creating communication difficulties and safety concerns. Wall treatment proves impractical due to the scales involved.

Cost-effective coverage makes ceiling baffles attractive for industrial applications. Strategic placement over work areas controls local noise while general installations manage overall reverberation throughout large spaces.

Safety considerations drive material selection and installation methods. Non-combustible materials may be required near heat sources. Easy access for maintenance accommodates industrial cleaning schedules and equipment modifications.

Manufacturing facilities value improved communication without interference with production processes. Clear speech enhances safety and efficiency while reducing noise fatigue that affects worker satisfaction.

Technical Considerations: What You Need to Know

Here are some technical components you need to take care of:

Acoustic Performance Standards

Sound absorption ratings help compare different baffle systems, but the numbers require interpretation. NRC (Noise Reduction Coefficient) ratings provide basic comparisons – higher numbers mean better absorption. Quality baffles typically achieve NRC ratings between 0.80-0.95.

However, frequency-specific performance matters more for real applications. Most commercial noise problems occur in speech frequency ranges (500-2000 Hz). Materials performing well in these ranges solve practical problems regardless of overall NRC ratings.

Coverage requirements depend on ceiling height, room size, and existing surface materials. Spaces with 3-4 metre ceilings typically need 15-25% baffle coverage for noticeable improvement. Higher ceilings require proportionally less coverage due to natural sound attenuation.

Reverberation control provides the most noticeable acoustic improvement in most commercial spaces. Quality baffle installations reduce reverberation time, making speech clearer and reducing overall noise levels.

Structural Requirements

Ceiling capacity determines what baffle systems are possible. Most commercial buildings handle standard baffle loads without structural modifications. However, extensive installations or unusually heavy systems may require structural evaluation.

Suspension methods affect both performance and appearance. Cable suspension provides a clean visual appearance with reliable support. Grid systems enable modular installation and easy reconfiguration. Rigid mounting offers precise positioning for architectural applications.

Seismic considerations become important in earthquake-prone regions. Flexible suspension systems accommodate building movement without damage. Proper design prevents baffles from becoming safety hazards during seismic events.

Load distribution across multiple attachment points reduces stress on individual ceiling connections. Professional installation ensures proper load calculations and appropriate hardware selection for long-term reliability.

Fire Safety and Building Codes

Material fire ratings determine code compliance for suspended installations. Most commercial applications require Class A fire-rated materials or non-combustible systems. Institutional facilities often mandate non-combustible materials regardless of other ratings.

Installation compliance involves sprinkler system coordination. Suspended baffles cannot interfere with water distribution patterns or reduce coverage below designed levels. Some systems integrate sprinkler heads within baffle structures for a clean appearance.

Emergency lighting must maintain required illumination levels throughout spaces. Baffle placement cannot create dark areas that compromise safety. Some installations require integrated emergency lighting within baffle systems.

Building code variations across regions create compliance challenges. Local authorities may impose requirements beyond national standards. Early consultation with building officials prevents costly modifications during construction.

Installation Considerations: Planning for Success

Now, here are the aspects you need to keep in mind when it comes to installing baffles:

Pre-Installation Planning

Structural assessment identifies ceiling capacity and attachment options. Most commercial buildings accommodate standard baffle installations, but verification prevents problems during construction. Heavy systems or extensive coverage may require supplemental structure.

Coordination with other ceiling systems prevents conflicts and optimises performance. HVAC ductwork, lighting fixtures, and fire safety systems compete for ceiling space. Early coordination meetings prevent costly field modifications.

Access requirements for future maintenance affect installation design. Suspended baffles must allow access to ceiling-mounted equipment. Some installations feature removable sections or hinged panels that facilitate maintenance without system removal.

Mock-up installations verify performance and appearance before full implementation. Complex projects benefit from testing acoustic performance, visual impact, and installation procedures before committing to complete systems.

Installation Methods

Grid-based systems provide modular flexibility with standardised components. Ceiling grids accommodate various baffle sizes and configurations. Future modifications become straightforward when expansion or reconfiguration needs arise.

Individual hanging methods offer design flexibility with custom positioning. Cable suspension provides a clean appearance with minimal visual impact. Rigid mounting enables precise positioning for architectural alignment requirements.

Phased installation minimises disruption in occupied buildings. Night and weekend work accommodates business operations. Sequential installation allows immediate benefits while work continues in adjacent areas.

Quality control ensures installation meets design intent and performance expectations. Professional installation teams understand coordination requirements and workmanship standards that ensure long-term success.

System Integration

HVAC coordination balances acoustic goals with air distribution needs. Baffles can enhance air mixing while providing sound control. Some installations incorporate air diffusers within baffle structures for integrated performance.

Lighting integration transforms functional baffles into architectural features. LED systems within baffles provide accent lighting while controlling acoustics. Programmable lighting enables different scenarios based on space usage.

Fire safety system coordination ensures code compliance while maintaining acoustic performance. Sprinkler coverage cannot be compromised. Smoke detection systems must maintain adequate coverage throughout spaces.

Technology infrastructure increasingly requires coordination with baffle installations. Wi-Fi access points, security cameras, and audio systems need ceiling access that baffle placement must accommodate.

Customisation Options: Making Baffles Work for Your Design

Here’s what many designers and architects spend more time on: How do you go about customisation?

Size and Configuration

Standard baffle dimensions accommodate most commercial applications while enabling cost-effective manufacturing. Common sizes range from 150mm to 600mm wide with lengths up to 2400mm for manageable installation.

Custom sizing addresses unique architectural requirements. Non-standard widths create a visual rhythm that complements specific design features. Custom lengths eliminate joints for a cleaner appearance in long runs.

Modular systems enable flexible configuration and future adaptation. Standardised components connect in various arrangements. Modular designs accommodate changing space requirements without complete reinstallation.

Geometric variations expand design possibilities beyond rectangular forms. Curved baffles complement architectural features. Angular forms create contemporary statements. Complex installations combine multiple shapes for artistic effect.

Surface Treatments

Material finishes affect both appearance and performance. Wood stains range from natural clear finishes to opaque colours that coordinate with interior palettes. Metal powder coating enables unlimited colour options with excellent durability.

Fabric selection balances acoustic performance with aesthetic goals. Commercial-grade acoustic fabrics optimise sound absorption while offering extensive design options. Custom printing enables corporate graphics or artistic designs.

Texture treatments add visual interest while maintaining acoustic effectiveness. Perforated patterns in wood and metal create depth and shadow lines. Fabric weaves provide subtle texture variations that enhance lighting effects.

Speciality finishes address unique requirements. Antimicrobial treatments support healthcare applications. UV-resistant finishes prevent fading in naturally lit spaces. Easy-clean finishes simplify maintenance in institutional environments.

Lighting and Technology Integration

LED integration transforms baffles from functional elements into architectural lighting features. Linear lighting within baffle channels provides accent illumination. End-lighting creates dramatic effects while maintaining acoustic function.

Smart lighting systems enable responsive environments that adapt to changing conditions. Occupancy sensors adjust lighting based on space usage. Daylight sensors maintain consistent illumination as natural light changes.

Technology integration accommodates modern building requirements. Wi-Fi access points, security cameras, and audio systems integrate within baffle structures to reduce ceiling clutter while maintaining clean acoustic installation.

Control systems enable lighting scenarios that support different activities. Meeting modes, presentation settings, and cleaning cycles can be programmed for optimal lighting and acoustic performance.

Cost Considerations: Investment and Value

When it comes to costs, here’s what you need to remember:

Initial Investment Factors

Material costs vary significantly by type and performance level. Fabric-wrapped systems provide excellent performance at moderate cost. Wood baffles command premium pricing but offer superior aesthetic integration. Metal systems balance cost with durability.

Customisation adds cost but enables design integration that justifies premium pricing. Standard colours and sizes provide cost-effective solutions. Custom options address specific design requirements at 25-50% cost premiums.

Installation complexity affects total project costs. Simple grid-mounted systems require minimal labour. Complex custom configurations increase installation time and coordination requirements.

Project size influences unit costs through manufacturing efficiency. Large installations benefit from setup cost distribution. Small projects face proportionally higher engineering and fabrication costs.

Lifecycle Value

Energy efficiency benefits may offset installation costs through reduced HVAC requirements. Improved acoustic comfort often enables temperature adjustments that reduce energy consumption. Calculate potential savings based on space conditioning loads.

Productivity improvements provide quantifiable returns in office environments. Research consistently shows measurable productivity gains in properly designed acoustic environments. Value improvements based on employee costs and space efficiency.

Property value enhancement benefits building owners through improved lease rates and tenant retention. Quality acoustic environments support premium positioning in competitive markets.

Maintenance costs affect long-term ownership expenses. Fabric systems may require replacement after 12-18 years. Wood systems need periodic refinishing. Metal systems typically require only cleaning for decades of service.

Return on Investment

Productivity metrics demonstrate value in office environments. Proper acoustics reduces noise-related complaints and improves employee satisfaction. Professional environments benefit from enhanced client perception and communication quality.

Employee satisfaction improvements support recruitment and retention efforts. Acoustic comfort consistently ranks among the top workplace satisfaction factors. Quality acoustic environments contribute to corporate wellness initiatives.

Customer satisfaction in retail and hospitality environments directly impacts revenue. Restaurants with proper acoustics generate higher satisfaction scores and repeat visits. Retail environments with comfortable noise levels encourage longer shopping visits.

Brand enhancement value proves difficult to quantify but significantly impacts business success. Quality acoustic environments support professional image and client confidence across all commercial applications.

Specification and Procurement: Getting What You Need

So, what are the must-know specifications, and how exactly should you approach procurement?

Performance Requirements

Specify acoustic performance targets rather than just material requirements. Define target reverberation times and background noise levels for specific spaces. This ensures solutions address actual acoustic problems rather than just meeting material specifications.

Material quality specifications prevent the substitution of inferior products. Define minimum densities for acoustic cores, fire ratings, and environmental resistance appropriate for each application. Require certified test data from recognised laboratories.

Installation quality standards ensure field performance matches design intent. Specify alignment tolerances, suspension methods, and workmanship standards. Define inspection procedures and acceptance criteria.

Warranty requirements protect long-term performance and investment. Require material warranties covering manufacturing defects and installation warranties addressing workmanship issues. Define response times for any problems that arise.

Selection Criteria

Acoustic performance should drive material selection before aesthetic preferences. Understand frequency-specific requirements for your application. Verify performance claims through independent testing rather than manufacturer marketing materials.

Aesthetic integration affects long-term satisfaction and design success. Choose systems that enhance rather than compromise architectural vision. Consider how baffles will age and whether they’ll remain appropriate for evolving space uses.

Maintenance requirements influence long-term costs and appearance. Understand cleaning procedures, replacement cycles, and component availability. Factor maintenance costs into lifecycle value calculations.

Fire safety compliance ensures code approval and occupant safety. Verify material ratings and installation methods meet local building codes. Consult fire protection professionals for complex applications.

Vendor Evaluation

Experience with similar projects indicates the capability to deliver successful results. Review portfolios demonstrating projects of comparable size and complexity. Verify references from recent installations in similar applications.

Manufacturing capabilities affect quality, cost, and delivery schedules. In-house manufacturing provides better quality control and shorter lead times. Advanced equipment enables custom solutions at competitive pricing.

Installation support ensures proper field implementation. Experienced teams understand coordination requirements and quality standards. Project management capabilities keep installations on schedule and within budget.

Technical support helps optimise design and performance. Acoustic consulting capabilities ensure appropriate material selection and system design. Post-installation support addresses any issues that arise during building operation.

Future Trends: What’s Coming Next

Based on our analysis of the market, here’s what architects and designers can expect in the coming years:

Sustainable Materials

Environmental responsibility drives innovation in acoustic materials. Recycled content options provide excellent performance while supporting sustainability goals. Bio-based materials offer end-of-life solutions that eliminate disposal concerns.

Life cycle assessment guides material selection for minimum environmental impact. Local sourcing reduces transportation emissions while supporting regional economies. Sustainable manufacturing processes reduce energy consumption and waste generation.

Circular economy principles influence design for material recovery and reuse. Modular systems enable component replacement without complete system disposal. Design strategies facilitate future material recovery when renovation occurs.

Green building certification programs increasingly recognise acoustic design contributions. LEED and other standards value acoustic comfort alongside energy efficiency. Quality acoustic environments support wellness credits in green building programs.

Smart Building Integration

Technology integration enables responsive acoustic environments. Environmental sensors monitor noise levels and adjust systems automatically. Smart lighting within baffles adapts to occupancy and activity patterns.

Building automation systems coordinate acoustic, lighting, and HVAC systems for optimal performance. Integrated controls enable programmed scenarios that support different space uses. Data collection supports maintenance scheduling and performance optimisation.

Predictive maintenance systems use sensor data to anticipate service needs. Performance monitoring identifies gradual degradation before problems affect occupant comfort. Automated scheduling optimises maintenance timing to minimise business disruption.

Wireless connectivity enables remote monitoring and control. Building managers can adjust lighting and monitor acoustic performance from central locations. Integration with facility management systems supports comprehensive building operation strategies.

Design Evolution

Biophilic design trends incorporate natural forms and materials that support human wellness. Organic shapes complement natural lighting and vegetation in building design. Research continues to quantify the wellness benefits of nature-inspired acoustic solutions.

Artistic integration elevates acoustic treatment to architectural art. Collaborations with artists create unique installations that serve multiple purposes. Digital integration enables dynamic graphics that change based on content or schedule.

Mass customisation makes unique solutions accessible at competitive pricing. Advanced manufacturing enables site-specific designs that respond to unique architectural conditions. Parametric design tools optimise both acoustic and aesthetic performance simultaneously.

Interactive elements respond to occupant presence and activity. Motion sensors trigger lighting changes as people move through spaces. Some systems respond to sound levels with visual feedback that creates engaging environmental experiences.

Takeaway

Start acoustic planning early in the design process rather than treating it as a later consideration. Acoustic problems are much easier and less expensive to prevent than to fix after construction completion.

Define specific acoustic objectives based on space usage and occupant needs. Generic “noise reduction” goals rarely lead to satisfactory results. Quantify target improvements in reverberation time, background noise levels, and speech clarity.

Coordinate with all building systems during design development. Acoustic, structural, HVAC, lighting, and fire protection systems must work together for optimal results. Early coordination prevents conflicts that compromise both performance and budgets.

Work with experienced acoustic professionals who understand both technical requirements and design integration. Successful projects require expertise in acoustic engineering, architectural coordination, and installation best practices.

At Unidus Acoustics, we specialise in custom acoustic solutions that deliver measurable performance improvements while enhancing architectural design. Our 40 years of expertise enable optimal material selection, system design, and installation coordination for commercial projects of any complexity.

Contact our design team to discuss your specific acoustic challenges and explore ceiling baffle solutions tailored to your performance requirements and aesthetic objectives. We provide comprehensive acoustic consulting, custom manufacturing, and professional installation services that ensure project success from concept through completion.

Ready to transform your space with ceiling baffles that work as hard as they look good?