You’re specifying acoustic panels for a corporate office project in Gurgaon. A quick search returns dozens of acoustic panel manufacturers and suppliers, all claiming superior performance, competitive pricing, and reliable delivery. Their websites look professional. Their product photos are impressive. How do you distinguish between companies that will deliver what your project needs and suppliers who’ll create problems you don’t discover until it’s too late?

The acoustic panel market has expanded rapidly, bringing genuine innovation alongside questionable claims. Understanding what separates leading acoustic panel companies from generic suppliers isn’t about comparing product catalogues. It’s about recognising the capabilities, knowledge, and commitment that determine whether your acoustic treatment actually works.

Technical Knowledge and Engineering Capability

The first separator is technical depth. Leading acoustic panel companies understand acoustics as an engineering discipline. They can explain why specific panel configurations work for particular applications, how different materials affect acoustic performance, and what performance targets are realistic for your space.

Generic suppliers treat acoustic panels as products to sell rather than solutions to engineers. They’ll tell you their panels have “excellent sound absorption” without explaining what that means for your specific application. They can’t discuss reverberation time, speech intelligibility, or how ceiling height affects panel performance because they don’t actually understand these concepts.

This knowledge gap reveals itself in conversations. Ask a leading company how many panels you need for a specific space, and they’ll ask about room dimensions, ceiling height, wall materials, and intended use before answering. Ask a generic supplier the same question, and they’ll give you a square metre calculation without context.

Technical capability also shows in product development. Leading acoustic panel companies invest in research, testing, and innovation. They improve materials, refine manufacturing processes, and develop new solutions for emerging acoustic challenges. Generic suppliers source products from manufacturers and rebrand them without any engineering input or product development.

Manufacturing Quality and Control

Technical expertise means little without the manufacturing capability to deliver on it. Where and how acoustic panels are manufactured determines their performance consistency and longevity. Leading acoustic panel manufacturers control their manufacturing process. They understand that acoustic performance depends on precise material composition, consistent thickness, and proper density. Manufacturing variations that seem minor can significantly affect acoustic properties.

This control extends through the entire production process. Material sourcing follows specifications that ensure consistency. Manufacturing processes include quality checkpoints that catch variations before they become installed problems. Finished products undergo inspection to verify they meet performance specifications.

Generic suppliers typically don’t manufacture their panels. They source from various manufacturers, often choosing based on price rather than quality. This means inconsistent performance between batches, panels that don’t match specifications, and no accountability when problems arise because the supplier doesn’t control the manufacturing.

The manufacturing question is simple: Does the company you’re considering make what they sell, or do they buy it from someone else? The answer reveals whether they can truly guarantee performance or whether they’re just intermediaries hoping everything works out.

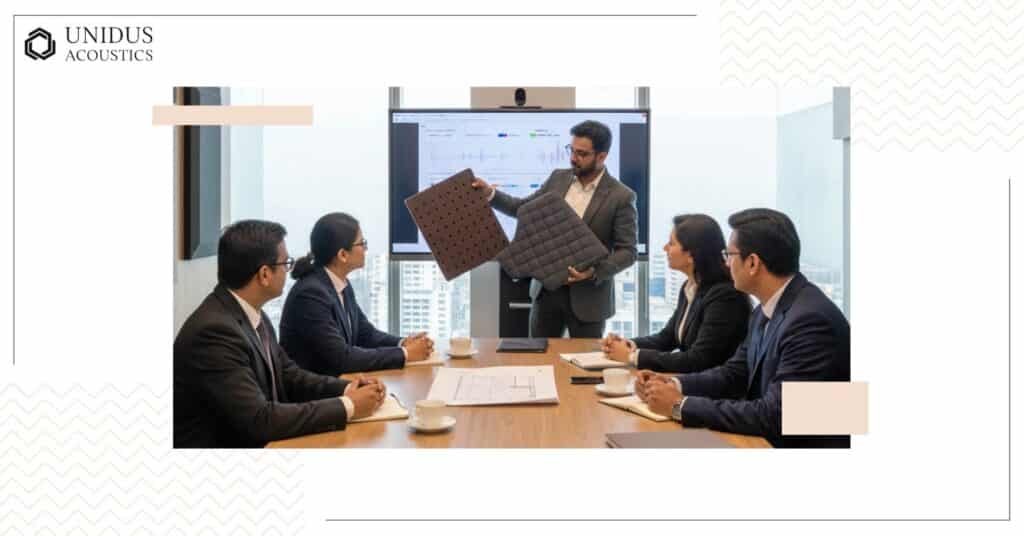

Customisation Capability

Manufacturing control becomes particularly critical when projects require customisation. Real projects rarely fit neatly into standard product offerings. Ceiling heights differ. Spaces have unusual dimensions. Brand guidelines require specific colours. Acoustic requirements vary by zone. Leading acoustic panel companies can customise solutions to meet these realities.

Customisation capability requires manufacturing control, engineering knowledge, and design flexibility. It means understanding which modifications affect performance and which don’t. It means having manufacturing processes that can accommodate custom sizes, colours, and configurations without compromising quality or creating impossible lead times.

Generic suppliers offer what’s in their catalogue. If your project needs something different, they’ll suggest you modify your requirements rather than customising their product. This forces compromises that affect either your design vision or acoustic performance.

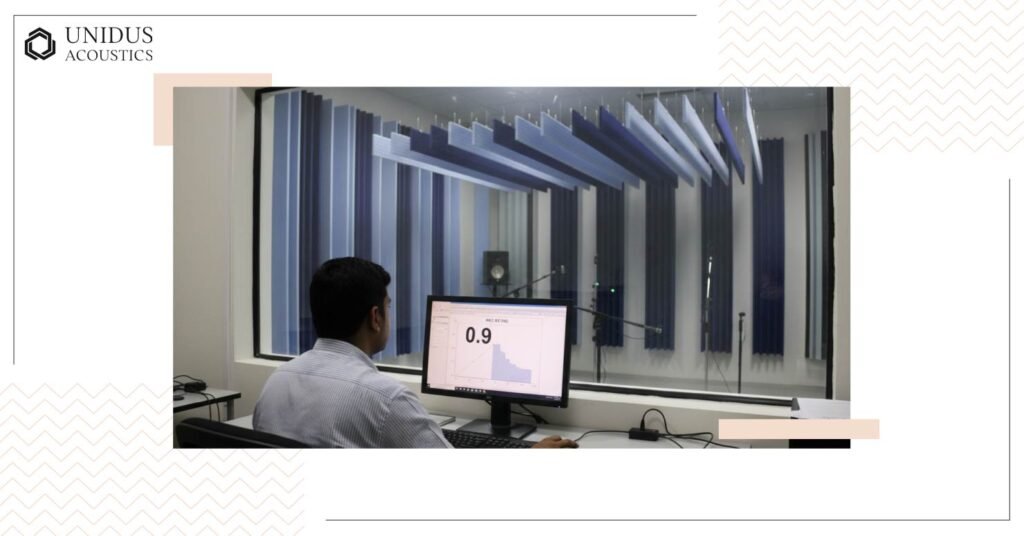

Testing and Performance Verification

Acoustic performance isn’t subjective. It can be measured, tested, and verified. Leading acoustic panel companies provide documented performance data from accredited testing facilities. They can show you NRC (Noise Reduction Coefficient) ratings, explain what those ratings mean, and discuss how their panels were tested.

This documentation matters because acoustic performance claims are easy to make and difficult to verify without proper testing. A panel might look identical to a high-performance product while delivering half the acoustic absorption because of internal material differences you can’t see.

Generic suppliers often provide suspiciously impressive specifications without supporting test data. Or they reference testing done on similar products by other manufacturers. Or they provide data from non-accredited sources that don’t follow standardised testing protocols.

When evaluating acoustic panel companies, ask for test reports. Leading companies provide them readily. Generic suppliers make excuses about why they can’t.

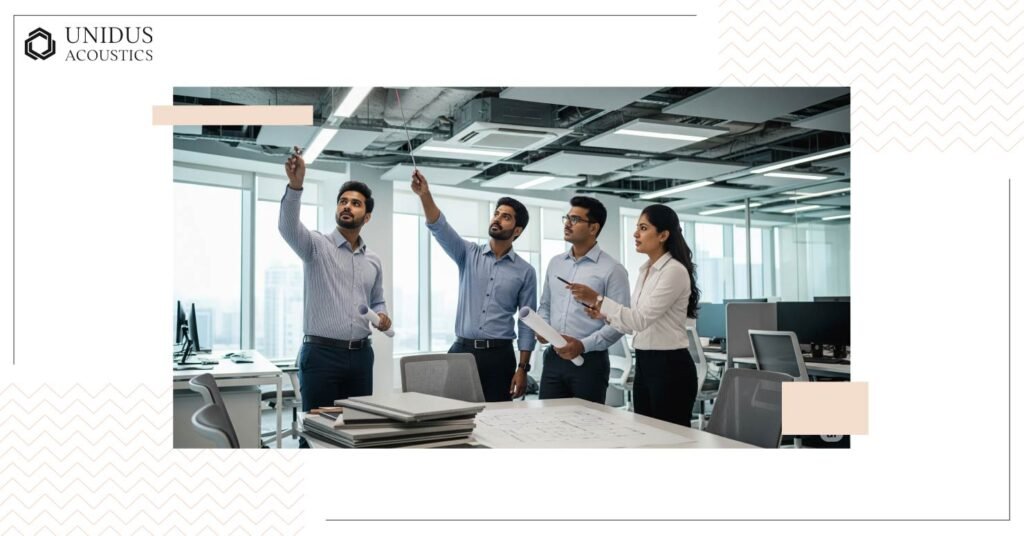

Project Support and Acoustic Planning

Acoustic panels are part of an acoustic solution, not the solution itself. Leading acoustic panel companies help you understand how panels fit into your overall acoustic strategy. They can assess your space, identify acoustic problems, and recommend where panels will be most effective.

This support includes acoustic analysis capabilities, even if informal. Understanding room acoustics, knowing how sound behaves in different spaces, and recognising which problems panels can solve versus which need different approaches.

Generic suppliers assume you’ve already determined everything. They’ll sell you panels but won’t tell you if you’re specifying them in the wrong places or choosing inappropriate types for your application. They’re order-takers rather than acoustic partners.

Experience with Real Projects

Experience matters tremendously in acoustics. Leading acoustic panel companies have worked on diverse projects, encountered unusual challenges, and developed solutions that aren’t in textbooks. This experience means they can anticipate problems, suggest proven approaches, and avoid mistakes that less experienced suppliers make repeatedly.

Ask about previous projects similar to yours. Leading companies can discuss specific challenges, how they addressed them, and what results were achieved. Generic suppliers show you photos without being able to discuss the acoustic problems those projects solved.

Experience also reveals itself in realistic timelines and honest assessments. Leading companies know how long custom manufacturing takes, what’s achievable within your budget, and when your requirements need adjustment to be practical. Generic suppliers tell you what you want to hear about delivery and capabilities, then fail to deliver.

Material Knowledge and Options

Acoustic panels use various materials (fabric, wood, metal, polyester, foam), each with different acoustic properties, durability characteristics, and appropriate applications. Leading acoustic panel companies understand these materials deeply. They can recommend materials based on your specific requirements rather than pushing whatever they stock.

This knowledge includes understanding how materials age, how they perform in different environments, and their maintenance requirements. A fabric panel appropriate for a corporate office might be completely wrong for a commercial kitchen. Leading companies know these distinctions. Generic suppliers treat all acoustic panels as interchangeable.

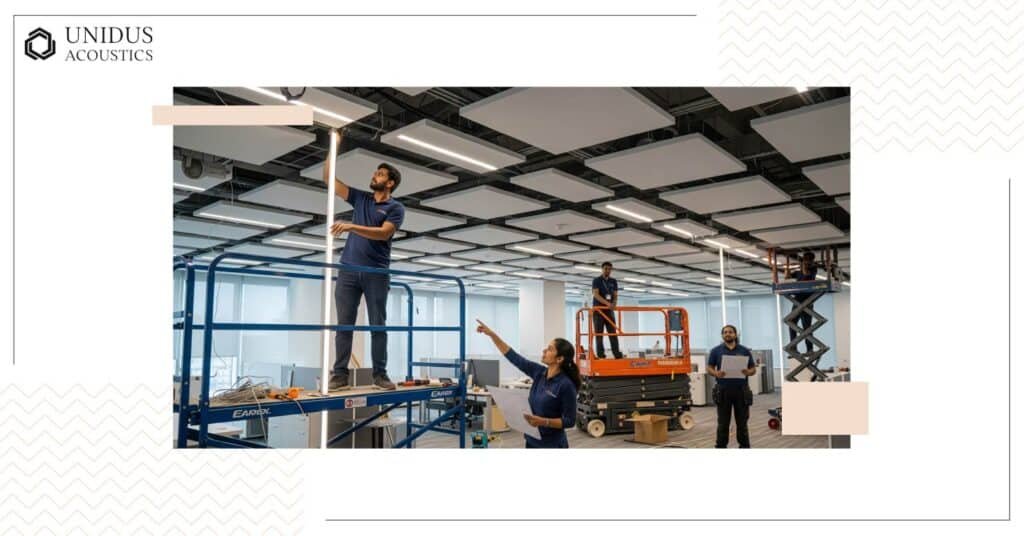

Installation Support and Follow-Through

Acoustic panels only perform properly when installed correctly. Leading acoustic panel companies provide installation support, detailed installation instructions, and sometimes installation services. They understand that improper installation can completely negate even the best panels.

Generic suppliers ship products and consider their job done. If installation problems arise, you’re on your own. If performance doesn’t match expectations, they’ll suggest the installation was wrong rather than acknowledging their panels might not meet specifications.

The Difference It Makes

The distinction between leading acoustic panel manufacturers and generic acoustic panel suppliers determines whether your acoustic treatment succeeds or fails. Leading companies deliver panels that perform as specified, arrive on time, and solve your acoustic problems. Generic suppliers create risks that emerge as project problems.

At Unidus Acoustics, our 40 years of expertise reflects everything discussed here: controlled manufacturing, engineering capability, extensive customisation, verified testing, and comprehensive project support. We don’t just supply panels. We deliver acoustic solutions that work.

Evaluating acoustic panel companies for your next project?

Get in Touch

Let’s discuss your specific acoustic challenges and how our 40 years of manufacturing expertise, custom design capabilities, and verified performance testing deliver solutions that work, not just products that arrive.