Your new office looks exactly right. Exposed ceilings, concrete, and floor-to-ceiling glass. That industrial aesthetic every designer wants right now. But here’s what nobody mentions: these beautiful hard surfaces create acoustic nightmares. Every conversation carries across the floor. Conference calls become public broadcasts. The space photographs beautifully, but works terribly.

Sound familiar?

We see this constantly in modern commercial projects across India.

Enter acoustic metal panels. These solutions deliver the industrial sophistication your design demands while solving the sound problems hard surfaces create. This combination explains why acoustic metal panels are rapidly becoming the specification of choice for architects and interior designers working on commercial projects.

The Material That Solves Two Problems

Metal in architecture signals quality, permanence, and modernity. It photographs beautifully. It ages gracefully. It integrates seamlessly with contemporary building systems. But acoustically, solid metal is a disaster. It reflects sound rather than absorbing it, creating exactly the kind of reverberant environment that makes spaces uncomfortable.

Traditional acoustic treatments solve the sound problem but compromise the aesthetic. Fabric-wrapped panels, foam tiles, soft materials that don’t belong in spaces designed around metal and glass.

Acoustic metal panels solve both problems simultaneously. They deliver the visual character of metal while providing genuine acoustic performance. This isn’t about disguising acoustic treatment as something else. It’s about engineering metal to perform acoustically while maintaining its material integrity.

How Acoustic Metal Panels Work

So how exactly do these panels achieve both goals?

The key to acoustic metal panels is perforation. Carefully engineered hole patterns allow sound waves to penetrate the metal surface and be absorbed by acoustic backing material behind the panel. The metal perforated ceiling tiles remain visually solid from normal viewing distances while functioning acoustically as an absorptive surface.

The perforation pattern itself becomes a design element. Different hole sizes, spacing patterns, and arrangements create varying visual effects while affecting acoustic performance. This gives designers control over both aesthetics and function.

The backing material (typically acoustic insulation or specialised absorptive materials) captures sound energy that passes through the perforations. The result is a panel that looks like metal but performs acoustically like a soft material.

At Unidus Acoustics, our metal acoustic solutions include perforated metal ceiling tiles, metal baffles, and metal ceiling panels. With 40+ years of expertise and computational design capabilities, we engineer these systems to deliver precise acoustic performance while maintaining the architectural impact your project demands.

Why Modern Commercial Spaces Choose Acoustic Metal Panels

Several factors are driving architects and designers to specify acoustic metal panels in contemporary projects across India.

Aesthetic Compatibility

Modern commercial design favours industrial materials. Acoustic metal panels integrate seamlessly with this aesthetic language rather than working against it. They complement exposed ceilings, structural elements, and mechanical systems without looking like retrofit solutions.

Durability and Longevity

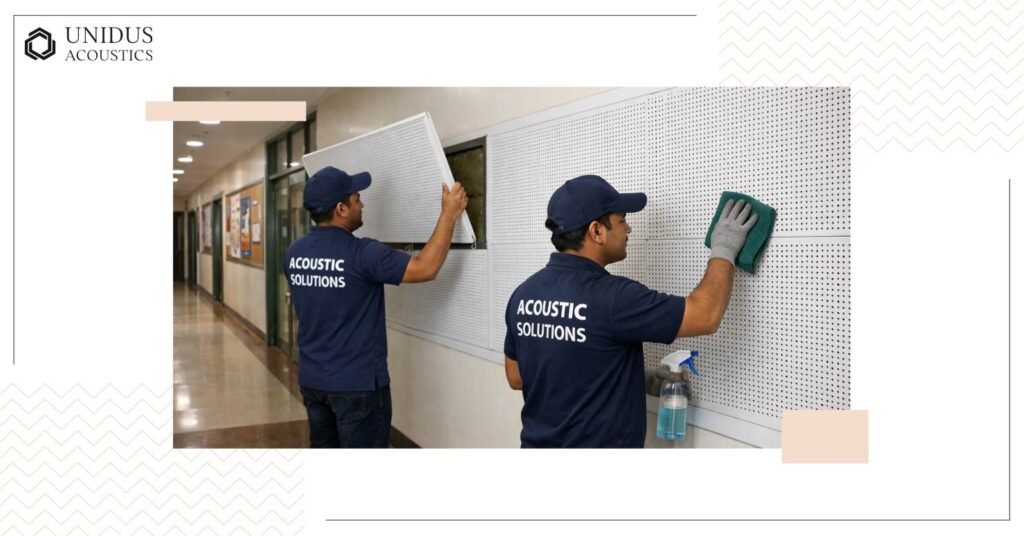

Commercial spaces need materials that withstand daily use, cleaning, and potential impact. Acoustic metal panels offer durability that fabric or foam-based treatments can’t match. This matters particularly in high-traffic areas, educational institutions, and hospitality environments where acoustic solutions must survive real-world use.

Hygiene and Maintenance

Metal panels are cleanable in ways that porous acoustic materials aren’t. This makes them suitable for healthcare environments, commercial kitchens, and food service areas where acoustic control is needed but hygiene standards are stringent. The non-porous surface doesn’t harbour dust, allergens, or bacteria.

Fire Safety

Metal inherently offers superior fire resistance compared to many traditional acoustic materials. This can simplify compliance with fire codes and insurance requirements, particularly in institutional buildings or spaces with strict safety standards. Our solutions meet international safety certifications including SGS and TUV standards.

Design Continuity

When a project’s material palette centres on metal (perforated screens, metal cladding, industrial finishes), acoustic metal panels maintain visual continuity. The acoustic treatment doesn’t read as a different material family added for functional reasons.

Applications Across Commercial Spaces

We’ve seen acoustic metal panels work effectively in diverse commercial environments across India, each benefiting from the material’s specific characteristics.

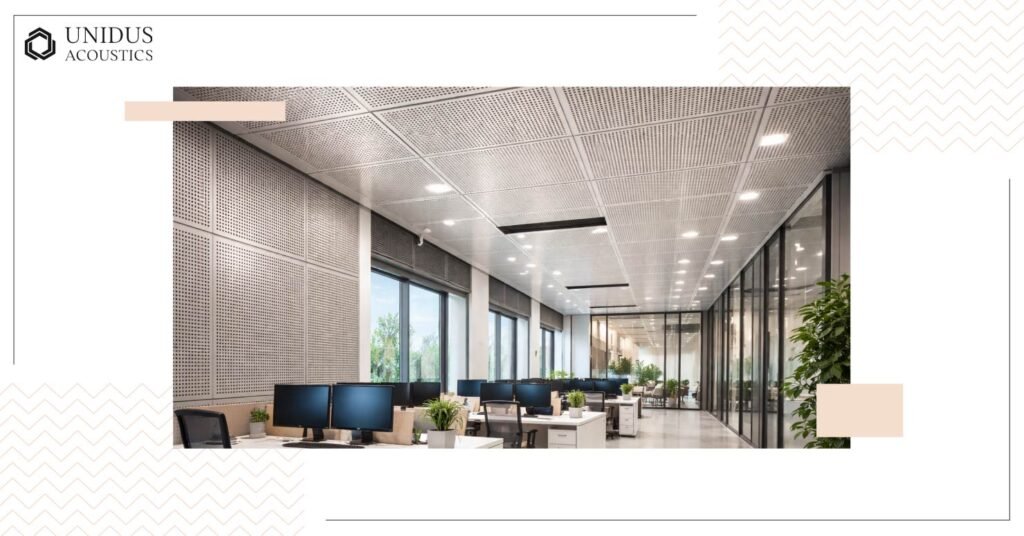

Corporate Offices

Modern offices with open ceilings and exposed services use metal ceiling panels and metal baffles to control sound without covering the industrial aesthetic. These solutions provide necessary absorption while reinforcing the design intent. We’ve seen tech campuses in Bangalore, corporate headquarters in Gurgaon, and co-working spaces in Mumbai all benefit from this approach.

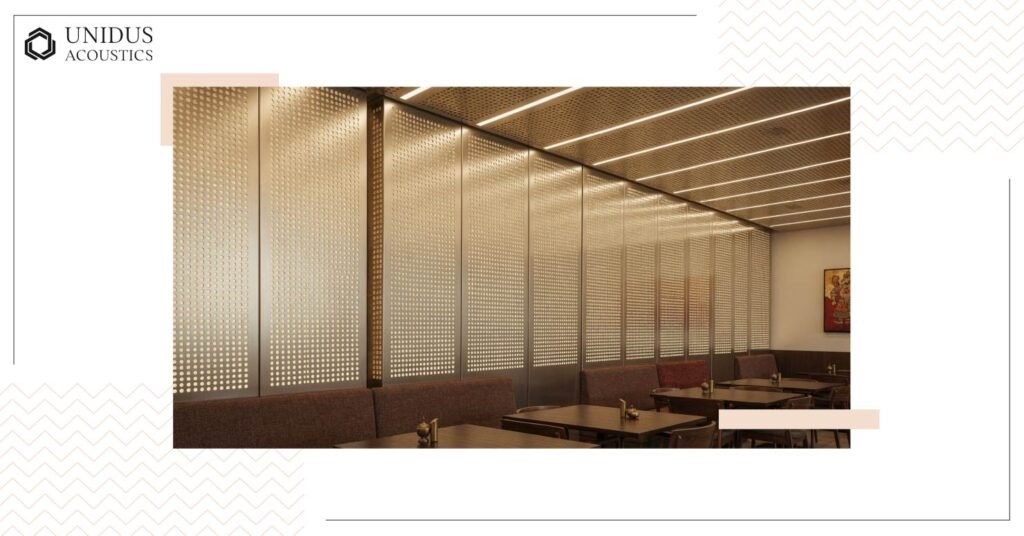

Restaurants and Hospitality

These spaces need durable acoustic solutions that can be cleaned regularly and withstand commercial kitchen environments. Acoustic metal panels deliver acoustic control in zones where fabric treatments would be impractical. The perforated acoustic ceiling installations work particularly well in open-kitchen restaurants where both aesthetics and hygiene matter.

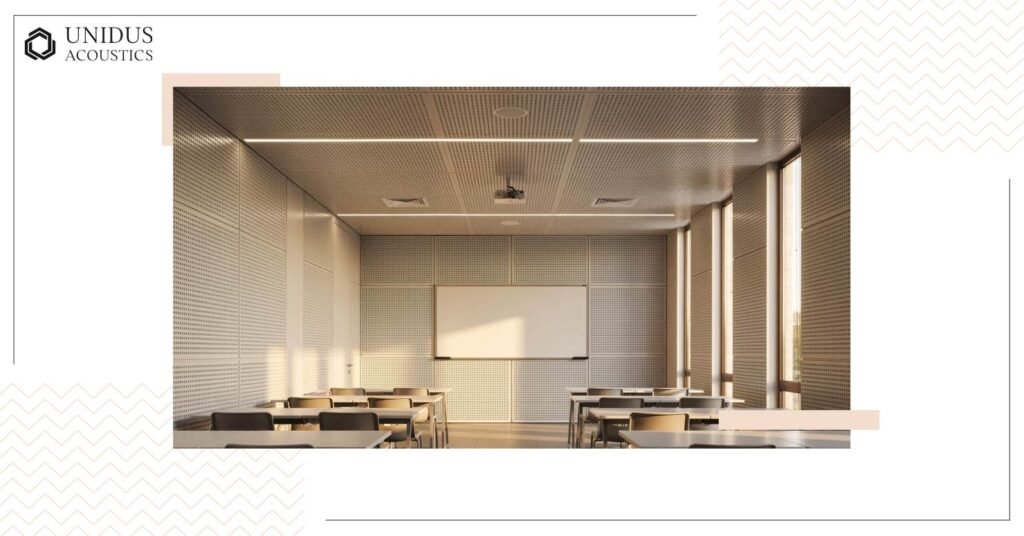

Educational Institutions

Schools and universities need acoustic solutions that survive student use and vandalism attempts. Metal panels provide acoustic performance with the durability institutional environments require. We’ve seen auditoriums, libraries, and collaborative learning spaces across India successfully integrate these systems.

Transportation Hubs

Airports, train stations, and transit facilities use acoustic metal panels because they offer acoustic control in high-traffic, high-impact environments where softer treatments would fail quickly. The metal perforated ceiling tiles withstand the demands of public infrastructure while managing the complex acoustics of large, reverberant spaces.

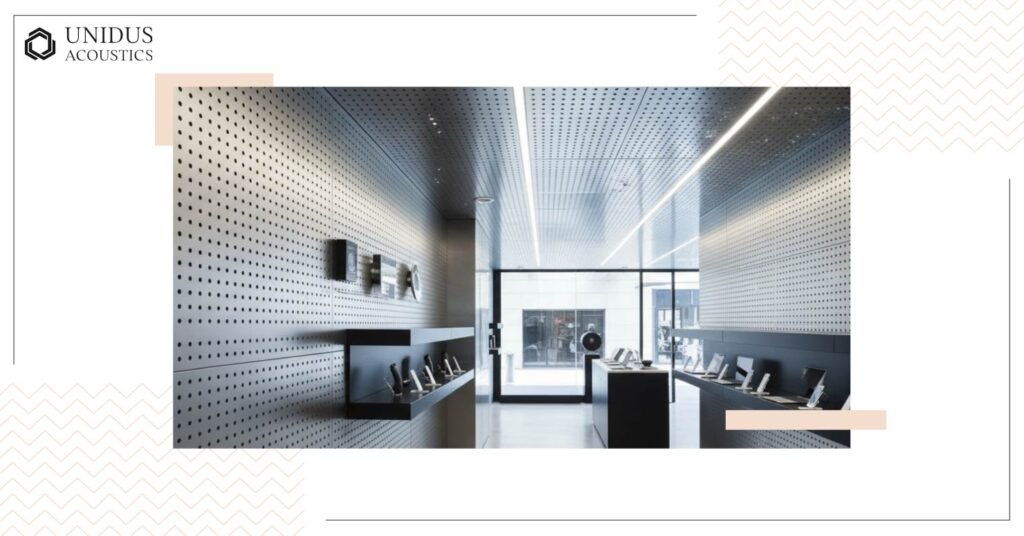

Retail and Commercial

Modern retail design often features industrial aesthetics. Acoustic metal panels control sound in large retail spaces while supporting the brand environment’s visual language. High-end retail in Delhi, Chennai, and other metros increasingly specifies metal acoustic solutions.

The Shift in Acoustic Design Thinking

The growing specification of acoustic metal panels reflects a broader shift in how architects approach acoustics. Rather than treating acoustic performance as something separate from material selection, contemporary design integrates acoustic function into material choices from the beginning.

Metal isn’t chosen despite acoustic needs. It’s chosen because acoustic metal panels deliver both the visual character and the functional performance the space requires. This integrated thinking produces better results than trying to add acoustic solutions to finished designs.

This approach aligns with current sustainability and wellness trends. Projects pursuing green building certifications and wellness standards increasingly recognise that acoustic comfort contributes to occupant health and productivity. Metal panels offer acoustic performance with material longevity, reducing replacement cycles and long-term environmental impact.

Making the Choice

Acoustic metal panels aren’t appropriate for every application. Spaces needing maximum acoustic absorption might require softer materials. Extremely tight budgets might necessitate different solutions. But for commercial projects where durability, aesthetics, and acoustic performance must all be high, acoustic metal panels increasingly make the most sense.

The key is working with an acoustic solutions provider who understands both the engineering and the design implications. Metal panels need proper backing materials, correct perforation patterns, and appropriate installation to perform as intended.

At Unidus Acoustics, we’ve spent 40+ years perfecting this approach. Our test and research centre allows us to validate acoustic performance before installation. Our computational design capabilities mean we can model both acoustic and visual outcomes. Our pan-India operations ensure consistent quality and on-time delivery, whether your project is in North, South, East, or West India.

Exploring acoustic metal panels for your next project?

Get in Touch to discuss how our metal acoustic solutions can deliver the industrial aesthetic and acoustic performance your commercial space needs.

Or simply reply with your project details, and we’ll share some ideas.