Specifying acoustic boards for a project should be straightforward. You know the performance requirements, aesthetic direction, and timeline.

Then reality hits.

Samples arrive perfectly. Specifications promise everything. The actual delivery? Doesn’t match what you signed off on. Colour variations that weren’t in the sample. NRC ratings that exist on paper but weren’t independently tested. Lead times stretch from 4 weeks to 12. Fire certificates showing up late, or worse, not covering the specific product variant you ordered.

These aren’t design failures. They’re vendor reliability issues that derail projects, especially now when hybrid workspace acoustics have made acoustic specification non-negotiable rather than nice-to-have.

When evaluating manufacturers, the right questions during vendor selection prevent these problems from surfacing mid-project when fixing them costs time and credibility.

Why Manufacturer Selection Matters More Than Initial Pricing

Every acoustic board manufacturer can send you a catalogue with impressive specifications and competitive pricing. What separates reliable suppliers from problematic ones only becomes clear when you’re three weeks from installation, and the “customised” panels arrive in standard sizes. Or when site inspections flag fire compliance issues with materials that supposedly had Class 1 certification.

The difference isn’t obvious during initial conversations. Any experienced vendor knows what architects need to hear. But the questions below reveal which manufacturers deliver consistently versus which ones create project complications.

9 Critical Questions Every Acoustic Board Manufacturer Must Answer

Here are nine critical questions that you must ask your acoustic board manufacturer before starting with your project:

1. Can You Provide Independent Testing Reports for Acoustic Performance?

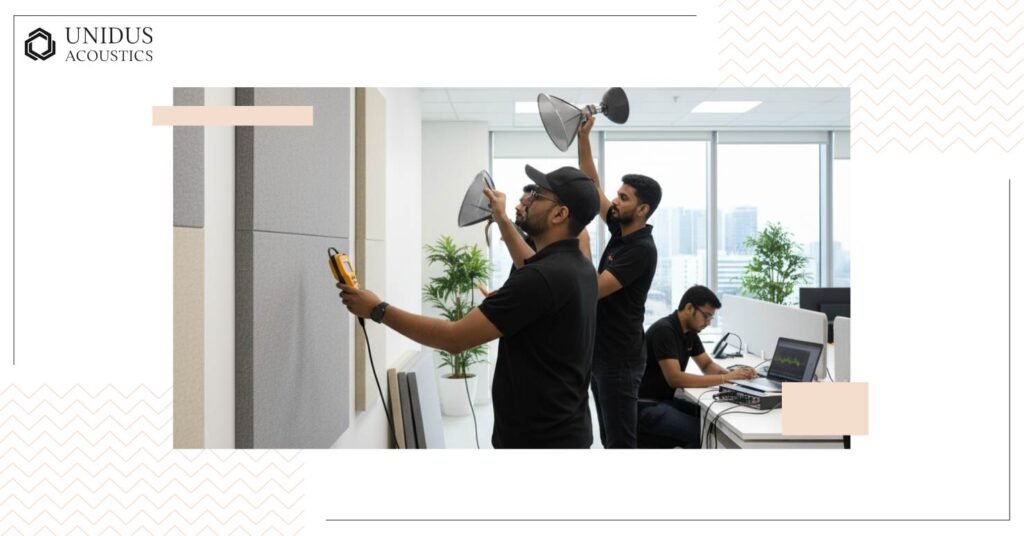

Generic NRC ratings mean nothing without third-party verification. When evaluating suppliers, ask for test reports from accredited laboratories (NABL-accredited in India, or international equivalents like ISO 354 testing). The report should specify the exact product configuration you’re specifying: thickness, backing material, and mounting method.

Check the testing date. Reports older than 5 years may not reflect current production methods. You need complete test methodologies, not summary results.

If a manufacturer can’t provide independent acoustic testing for their specific products, assume performance claims are estimates rather than verified data. For instance, all our acoustic panels carry NABL-accredited NRC testing with mounting-specific configurations documented, because architects need data they can defend during tender evaluations.

2. What’s Your Actual Customisation Capability and Process?

“Fully customisable” is standard marketing language. Get specific about what customisation means in practice.

Ask about dimensional flexibility upfront. Can they handle your 3-meter ceiling height? What about 15mm versus 25mm thickness? Edge profiles matter too (square cuts for minimalist designs, beveled for shadow lines, rebated for seamless installations). If they hesitate on any of these, their “fully customisable” claim needs scrutiny.

For aesthetic customisation, understand their colour matching process. Is it standard palettes or actual RAL/Pantone matching? What’s their resolution for printed panels? Can they handle 3D profiling and texturing, or just flat surfaces?

Then get into operational details. What’s the lead time difference between standard and custom specifications? Are there minimum order quantities for custom work? Most importantly, is customisation handled in-house or outsourced? Manufacturers with in-house fabrication capabilities handle customisation more reliably than those coordinating multiple subcontractors.

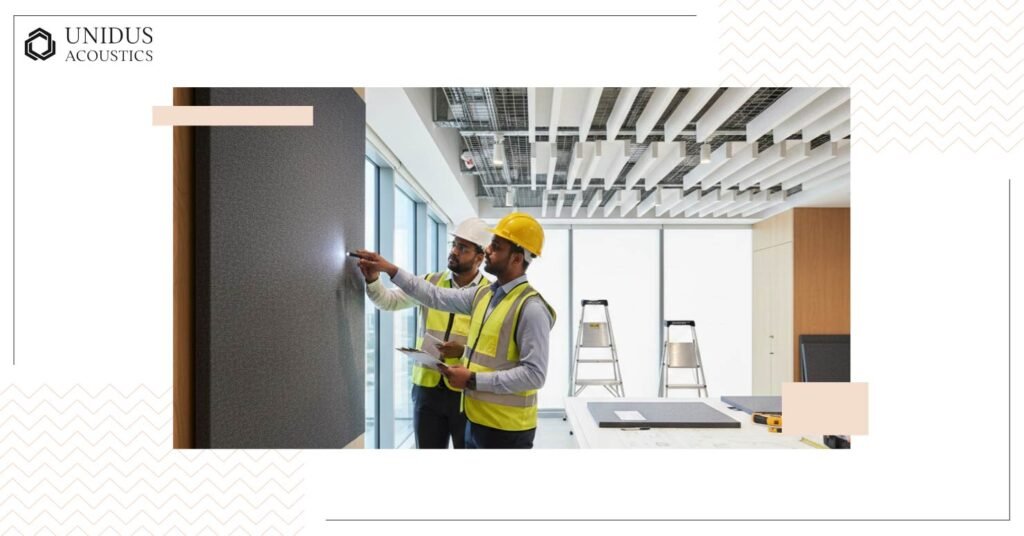

3. How Do You Handle Fire Safety Compliance Documentation?

Government and institutional projects require Class 1 or Class 0 fire ratings with complete documentation. Here’s what architects miss: fire certificates must cover the specific product variant you’re specifying. Core material, facing material, adhesives, and finishes all affect fire performance.

Ask if they can provide certificates before order placement, not at delivery. Find out whether fire tests were conducted in India or internationally (some tender requirements specify Indian testing). If product composition changes, do they re-certify and notify existing clients?

Fire compliance shouldn’t be a last-minute scramble. Professional manufacturers treat certification as ongoing quality control rather than a paperwork exercise.

4. What’s Your Production Lead Time and How Reliable Is It?

Standard lead times quoted during initial discussions often don’t account for raw material procurement delays, customisation complexity, current production backlog, shipping buffers, or quality control time.

Ask for lead time breakdowns: raw material procurement, production, quality check, and delivery. Better yet, ask for their average quoted versus actual delivery time over the past 12 months. A manufacturer quoting 4 weeks who consistently delivers in 5-6 weeks is more reliable than one quoting 3 weeks with 8-week actual deliveries.

Request client references specifically about timeline performance. If multiple architects mention consistent delays from a particular supplier, that’s more useful than quoted lead times.

For time-sensitive projects, ask about expedited production capabilities and associated costs before you need them, not when you’re panicking about installation deadlines.

5. Do You Manufacture In-House or Distribute from Other Sources?

Many companies position themselves as acoustic board manufacturers when they’re coordinating production from multiple workshops. Understanding their actual manufacturing model affects quality consistency (batch-to-batch uniformity, material sourcing control), project flexibility (handling technical modifications mid-project, speed of resolving defects), and capacity to scale for large projects.

If the manufacturer produces in-house, ask to visit the facility. Manufacturers confident in their quality control welcome site visits. If they’re distributors, ask about their quality assurance process and how they handle specification changes when your MEP consultant decides acoustic panels need different perforation patterns two weeks before production.

6. Where Do Your Core Materials Come From and How Do You Ensure Consistency?

Acoustic performance depends heavily on core material quality. Ask about material sourcing: polyester fibre, mineral wool, glasswool, or wood wool suppliers. Do they have single-source or multiple supplier relationships? What happens when primary suppliers have shortages?

Understand their quality control. What’s their incoming material inspection process? How do they maintain batch consistency? What performance stability can you expect over time?

Manufacturers who control their material supply chain or have long-term supplier relationships deliver more consistent products than those buying opportunistically based on current pricing.

7. How Do You Ensure Colour Consistency Across Production Runs?

Colour matching between samples, initial production, and replacement panels six months later is surprisingly difficult with acoustic boards. Ask if they maintain colour standards with spectrophotometer matching or visual comparison.

Can they guarantee colour consistency if you need additional panels six months after initial installation? How do they handle colour variation complaints? What’s their acceptable tolerance for colour deviation?

For projects where aesthetic consistency matters (hospitality, corporate headquarters, retail), this question separates professional suppliers from ones you’ll fight with during defect negotiations. We maintain spectrophotometer-matched colour standards and guarantee consistency for replacement panels even 18 months post-installation, because colour mismatches in a hotel lobby or executive floor aren’t acceptable “variations.”

8. What Technical Support Do You Provide During Installation?

Even straightforward acoustic panel installations hit complications. Ask what support the manufacturer provides before installation (installation guidelines, substrate preparation requirements, adhesive recommendations, environmental conditions), during installation (technical representative availability, troubleshooting support, on-site consultation for complex installations), and post-installation (warranty implications if installation deviates from specifications, maintenance guidelines, long-term performance expectations).

Manufacturers who stand behind their products provide clear installation guidance and responsive support when things don’t go as planned.

9. How Do You Handle Defects and Warranty Claims?

Every manufacturer promises quality, but defect handling reveals actual commitment. Ask for specific processes: What constitutes a defect versus normal material variation? Response time for defect claims (24 hours? 48 hours? A week?)? Replacement product lead times for defective materials? Who covers costs for defective material removal and reinstallation?

Most importantly, can they provide references from architects about past warranty situations? References about how suppliers handled warranty issues tell you more than warranty documents themselves.

Red Flags When Evaluating an Acoustic Board Manufacturer

Watch for these warning signs during vendor evaluation:

- Reluctance to provide independent testing reports or references.

- Vague answers about customisation capabilities or lead times.

- Fire certificates that don’t match the specific product variant.

- No clear quality control process or facility visit policy.

- Pressure to commit before receiving complete technical documentation.

- Unwillingness to put lead times and specifications in writing.

Any manufacturer hesitant about transparency during the selection process will be harder to work with when project pressures increase.

Making the Final Decision on Your Acoustic Board Manufacturer

Choosing a manufacturer based solely on initial quotes and sample quality creates project risks. The questions above help identify manufacturers whose operational capabilities match what your projects require.

Compare responses across multiple suppliers. The one who answers these questions most transparently and comprehensively typically delivers the most reliable project outcomes.

Unidus Acoustics has built systems over 40 years of expertise that answer these questions with documentation, not promises. For projects where acoustic board quality and delivery reliability can’t be compromised, we provide the specifications, certifications, and technical support that make vendor selection straightforward rather than stressful.

Working on a project where acoustic performance can’t be an afterthought? We provide independent test reports, fire certifications, and technical specifications upfront—before you commit. Share your project details for product recommendations that match your design intent. Contact us now to partner with us for your next project.