Here’s something every architect knows but rarely admits: You can design the most stunning space in the world, but get the ceiling system wrong, and the entire project feels off.

Nine times out of ten, when a space doesn’t feel right, it’s the ceiling that’s letting the side down.

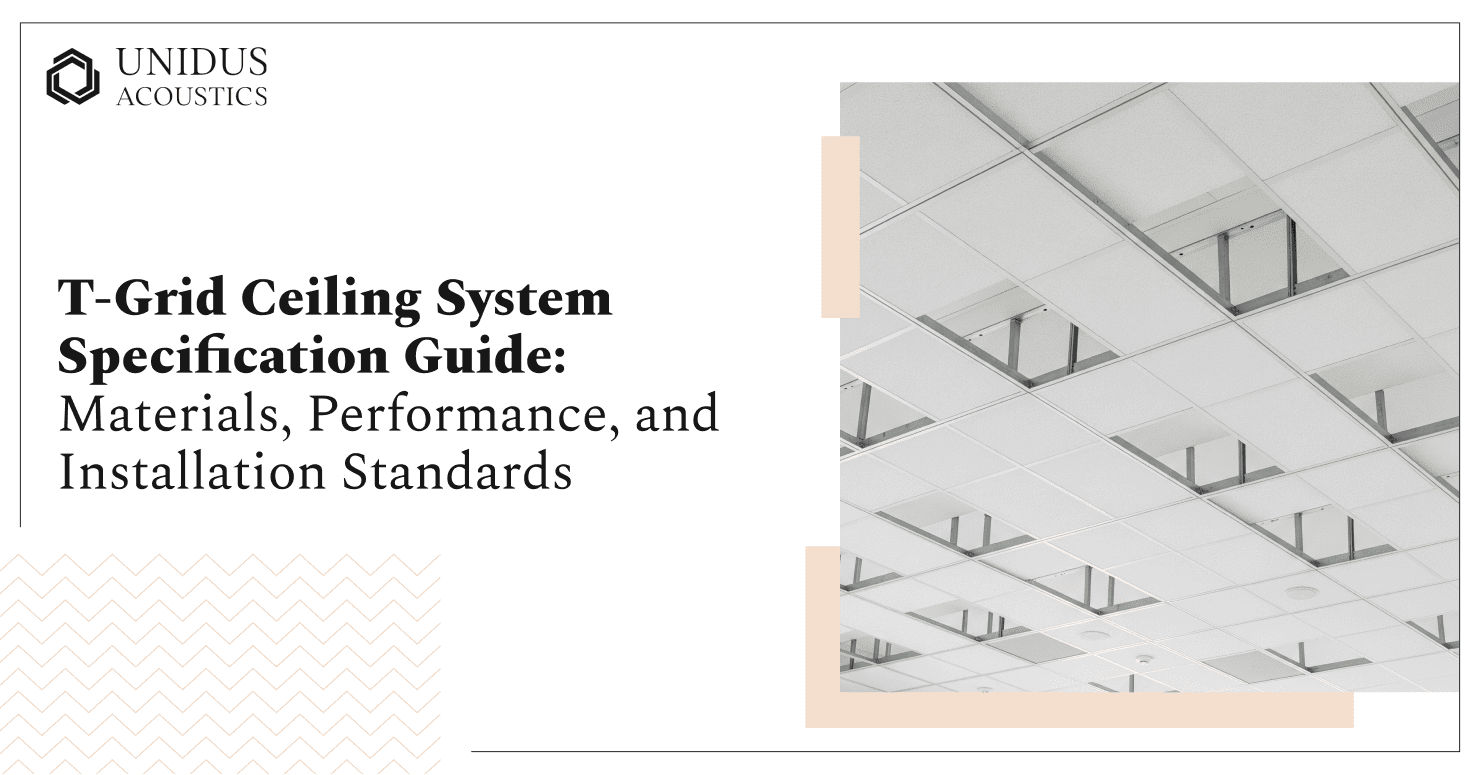

T-grid ceiling systems are the unsung heroes (or villains) of commercial design. When done properly, they disappear into the background, allowing your design vision to shine. When done poorly, they become impossible to ignore and constantly undermine everything else.

The truth is, most T-grid ceilings are specified as an afterthought. “Just put in a standard grid” becomes the default response when time pressures mount.

But here’s what 40 years in the acoustic solutions business has taught us at Unidus Acoustics: there’s no such thing as a ‘standard’ space, so why would there be a standard ceiling solution?

T-Grid Ceiling System: Getting the Materials Right

Here’s what you need to know when it comes to materials:

Steel vs Aluminium: The Great Debate

Hot-dip galvanised steel remains the reliable choice of metal for most applications. It handles loads up to 24 kg/m² without breaking a sweat and keeps its shape over decades. The galvanising process provides proper corrosion protection, which means your ceiling won’t start looking tatty after a few years of Mumbai’s humidity.

But aluminium? That’s where things get interesting.

In high-humidity environments like coastal projects or healthcare facilities, aluminium outperforms steel hands down. Yes, it’s more expensive upfront, but try explaining to your client why their beautiful ceiling system is showing rust stains after two monsoons.

Aluminium also makes sense when retrofitting heritage buildings, where every kilogram matters for structural loading.

Quality manufacturers maintain tight tolerances during roll-forming, which means your grid actually aligns properly during installation. Cheap systems with sloppy manufacturing? You’ll spend more time on site adjustments than you saved on material costs.

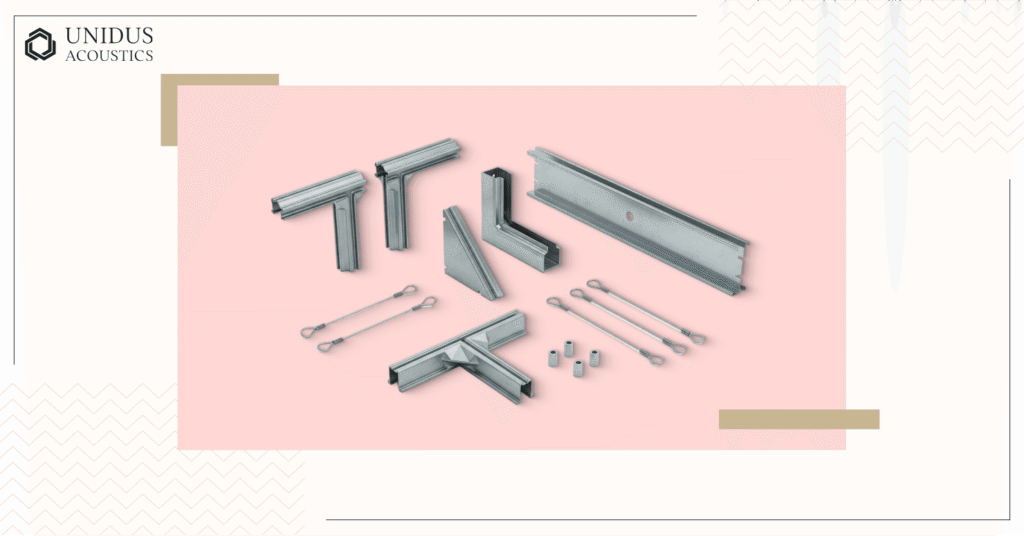

Connection Hardware: The Devil’s in the Details

Cross tees might look simple, but the connection mechanisms separate the professionals from the cowboys. Quality systems use precision-formed tabs that create proper mechanical connections.

You can actually feel the difference when components snap together – there’s a satisfying click that tells you everything’s locked in place properly.

Wall angles often get the least attention during specification, which is backwards thinking since they establish stability for your entire grid. Flimsy wall angles create edge deflection that shows up as gaps and misalignments – exactly the details that make clients question your attention to quality.

Hanger wire specification is where many projects go wrong. Using the right gauge wire at proper spacing isn’t optional – it’s basic engineering. The connection between hanger wire and grid is a potential failure point that demands proper specification and installation oversight.

Surface Finishes: Beyond Basic White

Standard white works fine, but contemporary projects increasingly demand something more sophisticated. Powder coating technology enables virtually any colour with excellent durability.

This opens up possibilities for ceiling systems that actually contribute to your design narrative rather than just staying neutral.

Wood-grain laminates have become particularly popular in corporate projects where clients want the warmth of natural materials without maintenance headaches. For healthcare environments, antimicrobial coatings provide real value beyond marketing claims, helping control infection transmission while maintaining aesthetic qualities essential for patient comfort.

T-Grid Ceiling System: Performance Specifications That Matter

So, what are the performance specifications that you should keep in mind?

Structural Performance: Getting the Basics Right

Load-bearing requirements go beyond simple weight calculations. The standard 24 kg/m² distributed load handles typical ceiling tiles plus reasonable maintenance access, but you need to think about concentrated loads too. What happens when maintenance staff place equipment on the grid during HVAC servicing?

Deflection limits aren’t just numbers in a specification – they’re what keep your ceiling looking professional over time. L/360 (deflection limit—the grid may bend at most 1 unit for every 360 units of span) for uniform loads and L/240 for concentrated loads, ensure that your grid maintains geometric integrity. Visible sagging is one of those details that clients notice immediately and remember forever.

Seismic considerations apply even in lower-risk areas. Proper bracing systems and connection details prevent catastrophic failure while accommodating thermal movement that occurs in all buildings.

Acoustic Integration: Where the Magic Happens

Your grid system doesn’t just hold acoustic tiles – it actively participates in the acoustic environment. Get this wrong, and your beautiful acoustic design becomes an expensive decoration.

NRC integration requires understanding how grid geometry affects acoustic performance. Standard 24mm face widths work well for most acoustic tiles while minimising visual impact, but this dimension affects acoustic coupling between tiles and plenum space. It’s the detail that separates good acoustic design from great acoustic design.

Cavity absorption optimisation depends on maintaining proper relationships between ceiling tiles, grid systems, and plenum characteristics. Gaps or misalignments create acoustic leaks that dramatically reduce overall performance. In open-plan offices where speech privacy matters, these details make the difference between productive work environments and noisy distractions.

Grid resonance frequencies merit attention in projects where low-frequency sound transmission is a concern. Quality steel systems avoid resonant frequencies within normal building operation ranges, preventing amplification effects that can turn minor noise issues into major problems.

Fire Safety and Environmental Considerations

Grid systems contribute to overall ceiling assembly fire ratings through material properties and connection details. Non-combustible steel and aluminium components support fire-resistant assemblies, but connection details must maintain integrity under fire conditions.

Environmental performance increasingly influences material selection as projects pursue green building certifications. Recycled content options exist in quality grid systems, while low-emission materials contribute to indoor air quality goals and potentially earn LEED credits.

Installation Standards of T-Grid Ceiling Systems: Where Theory Meets Reality

Here’s how you should approach installation standards:

Pre-Installation Planning: Setting Up for Success

Structural assessment starts with verifying that the existing structure can handle anticipated loads at the required hanger points. Grid layout optimisation involves more than mathematical calculations – experienced designers consider relationships between grid geometry, lighting layouts, HVAC components, and architectural features.

Level establishment requires precision beyond basic construction tolerances. Quality commercial ceiling systems maintain level tolerance within 3mm across any 6-metre span, demanding careful benchmarking and consistent reference points.

Quality Assurance During Installation

Hanger wire installation must follow engineering calculations rather than rule-of-thumb approaches. Runner levelling and alignment establish the geometric foundation for the entire system, using laser levels and precision measuring techniques.

Cross tee connection verification involves checking each connection point for proper engagement and mechanical integrity. This systematic verification prevents accumulated errors that can compromise entire grid sections.

Final Note

T-grid ceiling systems represent sophisticated solutions that demand thoughtful specification and quality installation to deliver their full potential. Success requires treating them as integral architectural elements rather than utilitarian necessities, demanding specifications that address aesthetic integration alongside structural and acoustic performance requirements.

At Unidus Acoustics, we specialise in custom acoustic solutions that transform ceiling systems from functional necessities into design assets. Our 40 years of expertise enables us to deliver bespoke solutions that balance form and function while ensuring on-time delivery and exceptional quality.

Whether you’re working on corporate offices, healthcare facilities, or educational environments, our technical team provides the engineering support and manufacturing precision necessary for professional results.

We turn complex ceiling challenges into elegant design opportunities that enhance the functionality and aesthetics of your space.

Ready to explore how properly specified T-grid ceiling systems can elevate your next project?

Our acoustic consultancy team is here to help you navigate the complexities and deliver solutions that work as beautifully as they perform.Discover our complete range of ceiling system solutions or schedule a quick consultation with our design specialists.